Worldwide leader in design, manufacturing, marketing and maintenance of on-line analyzers and sampling solutions.

See our products More about usCovering a world of industries

HOBRÉ TO ATTEND ATC 2024

April 15– 19, 2024

Galveston Island Convention Center, USA

Hobré would like to invite you to attend the ATC in Galveston and visit with our global team and have some hands-on time with our market leading analyzers. Hobré Analytical Solutions provides our clients with the analytical tools they need for fast, accurate, and reliable measurements to meet their process, quality, and compliance needs.

December 25, 2023

HOBRÉ PRISM RAMAN ANALYZERS REVOLUTIONIZE NITROGEN MEASUREMENT IN TEXAS, USA

Hobré proudly announces the successful startup of two PRISM Raman analyzers in Texas, USA. In the quest for optimal control of Nitrogen Recovery Units and to prevent off-spec gas from entering the pipeline, Hobré’s PRISM analyzers emerged as the preferred choice over traditional Gas Chromatographs (GCs).

Read more….

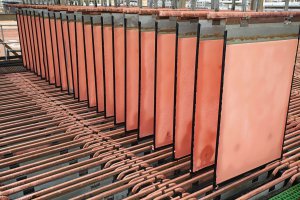

Since 1978, Hobré has provided proven solutions for the following industries: