“We have a strong preference for Hobré as system integrator because of their long experience in building sampling systems as well as their experience with a very broad range of different analysers”.

It is our goal to provide an innovative analyzing solution tailored to the specific requirements of our customer. We deliver analyzing solutions that provide more reliable information for our customers, to create an optimum process efficiency and reduced OPEX. Our experience has shown us that our approach consistently results in a quicker return on investment and a lower cost of ownership.

We provide customized analyzing solutions for the following industries:

- Oil & Gas; upstream, midstream, downstream.

- Dairy industry; complete solutions for spray-drying installations.

- Metal, mining and recycling industry

- Energy; combustion control meganisms

- Alternative energy: electricity to gas conversion/streams

- Renewables

- Steel and glass industry

Typical upstream analysis and sampling solutions

Water cut measurement

In various stages of production

Typical applications: At well, after separators, desalting outlet and export crude oil

Oil in water monitoring

For controlling and monitoring various stage of the produced water treatment

Typical applications: Separator outlets, Cyclone outlets, before overboard discharge.

H2S analysis in various stages of crude and gas processing

Typical applications: Separator outlets, Monitoring of H2S removal processes, sales gas metering.

Moisture measurement in gas production

Typical applications: Glycol dehydration control, Absorption bed regeneration control, sales gas monitoring.

Gas composition analysis with a Gas Chromatograph

Typical applications: typically in fractionation process and sales gas monitoring

Fuel gas quality with Wobbe Index Analyser and Gas Chromatograph

Typical applications: gas turbine and boiler control

Water quality analysis

Typically including : pH, Conductivity, turbidity, chlorine content dissolved oxygen etc

Typically including : Vapour pressure, density, Sulphur , Salt in Crude

Manual sampling

On various positions in the plant

Typical downstream analysis and sampling solutions

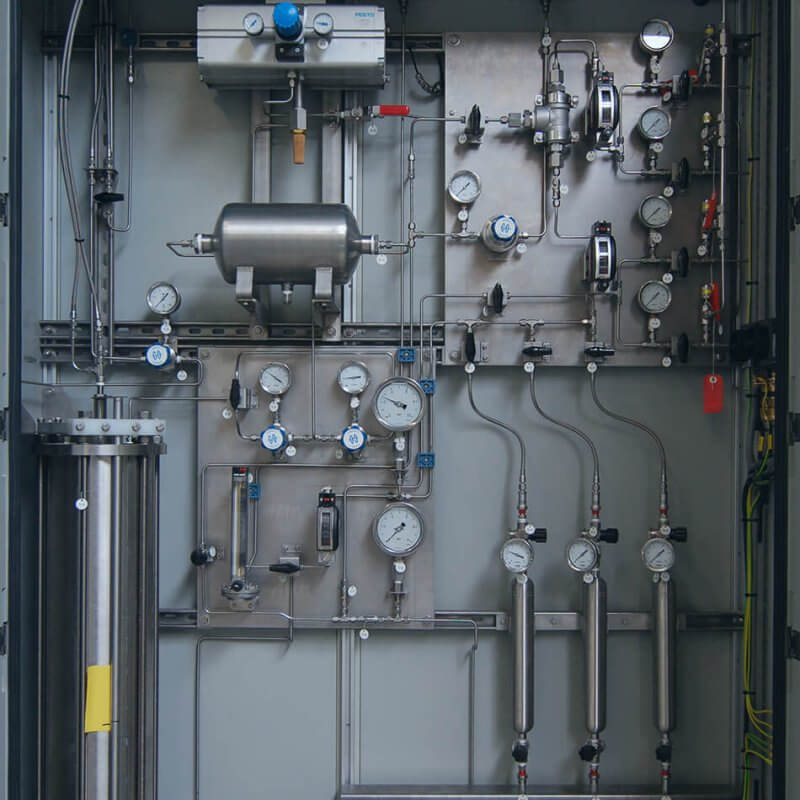

Analyzer houses

Executed in concrete, S304, SS316, Painted galvanized steel or GRP

Including:

- Heating, ventilation or complete HVAC systems.

- Safeguarding and safety systems

- Power distribution

- Completely assembled and tested before transport to site

Physical property Parameters

Typically including : Vapour pressure, Colour , Distillation, Flash point, Cloud point, Pourpoint, Viscosity etc.

Gas composition analysis with a Gas Chromatograph

For Gas and liquid applications

Typically including : O2 , O2/ Combustibles, CO analysis

Fuel gas quality with Wobbe Index Analyser and Gas Chromatograph

Typical applications: Furnace and boiler control

Typically including : pH, Conductivity, turbidity, chlorine, TOC etc

Manual sampling

On various positions in the plant

LNG analysis and sampling solutions

For LNG custody transfer it is now common practice to determine the composition and gross calorific value of delivered LNG by direct online analysis plus indirect lab analysis methods. The handling of the LNG before analyzing can have significant effect on the representivity of the sample. A sample which is not representative results in incorrect measurement which can have a significant financial impact. Hobré Instruments successfully supplied systems for these extreme conditions. This project scope was realized by:

- Take-off probe and vaporizer

- Automatic and spot sampling system

- Wobbe index analyzer

- Process gas chromatograph

- Sample conditioning system