Spray drying

Spray drying is a widely used technique for producing a dry powder from a liquid or slurry. Spray drying can be used for a wide range of products and is a preferred method for powdered products in the food, beverages, feed as well as the pharmaceutical industry. The safety but also efficiency of spray drying has become increasingly important for manufacturers, due to increasing demand, energy prices and environmental requirements. Manufacturers therefore face the challenge to improve efficiency, while keeping their operations continues, cost effective and most importantly safe!

Safety improvements

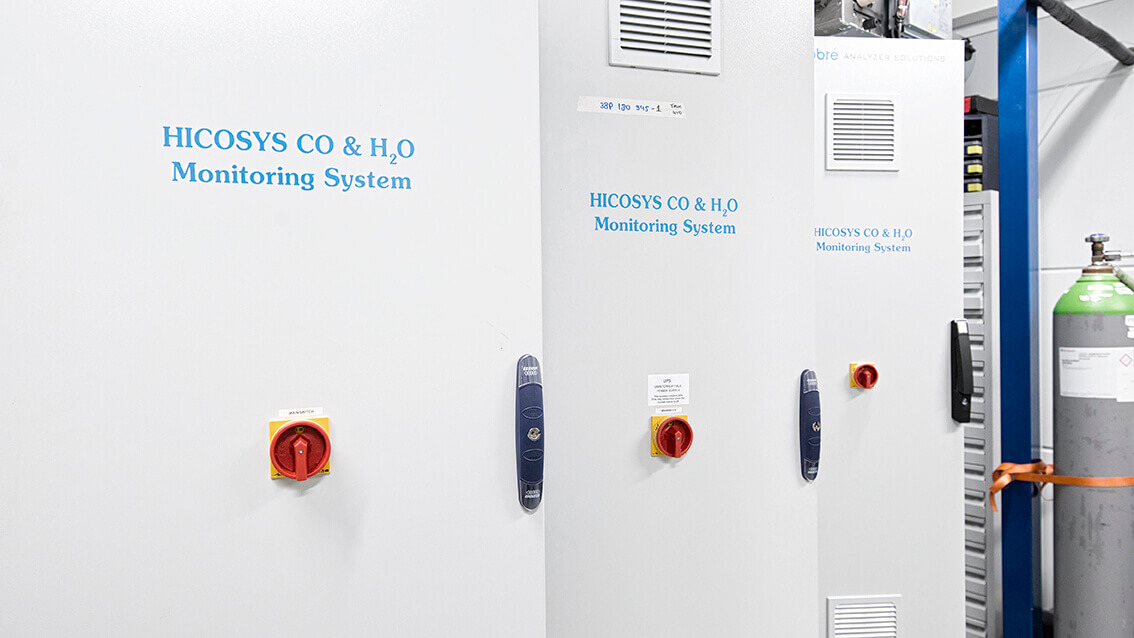

A product for example that is often spray dried is milk powder. Although the production of milk powder seems like a harmless production process, the opposite is true. Spray drying to produce powdered milk is a potentially hazardous process that must constantly be monitored to avoid major safety issues. CO detection is the only pre-warning protection method available to monitor spray dryers for any signs of thermal degradation (smolders) before they become potential hazards resulting in a fire or explosion. Hobré offers the high-end BICOSYS and HICOSYS ADVANCED analyzers to support you in your endeavors of safety improvements.

Efficiency improvement

Humidity is one of the most important parameters which can be used in maximizing the efficiency of spray drying operations, resulting in productivity gains up to 12%. Measurement of absolute humidity at elevated temperatures and high dust loads – in an accurate and reliable way – has always been a challenge for end-users. With our proprietary sampling probes, our analyzers are capable of measurement at the most challenging locations such as the tower exhaust, even before filtration by the cyclones and/or bag filters. Hobré offers the state-of-theart HICOSYS ADVANCED and HICOSYS AQUA analyzers to support you in your endeavors of efficiency improvement.