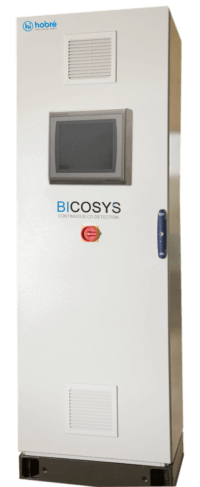

“The BICOSYS is our preferred choice for a CO detection system!

The unique dual analyzer setup ensures that in the unlikely event of an analyzer failure, process safety is guaranteed, and downtime avoided!”

Zero compromises in spray dryer safety

The BICOSYS is a high-end continuous CO detection system. The system monitors the incoming and outgoing CO concentrations to prevent false alarms due to high background CO concentration peaks in the wider environment, caused by trucks, exhaust pipes, fires, etc.

The BICOSYS distinct itself with a continuous measurement without the need of switching between the inlet and outlet, which leaves no window for false alarms!

The BICOSYS is by default equipped with two NDIR analyzers for continuous measurement of the inlet and outlet air, condensate coolers, UPS, wireless remote accessibility module for service & support, and dynamic flow-regulating sample probes depending on your production recipe or characteristics (such as fan speeds, product, temperature, etc.).

Even in the unlikely event of an analyzer failure, process safety and uptime are still guaranteed by the so-called limp mode. During the limp mode, the BICOSYS will operate based on a sequential measurement (altering between the inlet and outlet) by means of one of the two analyzers. This is the unmatched benefit of the BICOSYS’ unique dual analyzer setup. The advanced proprietary software of the BICOSYS mimics the flow behavior in the tower according to a set of tower specific characteristics. Thanks to our software, the BICOSYS has the lowest risk of false alarms in high and fluctuating background CO situations if compared to competition.

Also interested in:

CO & H2O Analysis in spray drying – Click here for the HICOSYS ADVANCED

H2O Analysis in spray drying – Click here for the HICOSYS AQUA