Key features

- The HIFISC system uses fluid flow as driving force in the sample preconditioning system’s fast loop. The fast loop flow through a 1/2” unrestricted loop is typically 25% of the pipeline velocity. The lag time in the probe is typically 0,2 to 2 seconds depending on the pipeline velocity.

- This approach offers a significant improvement compared to conventional systems where high-pressure gas and liquid in the sample probe are the main contributors of the total lag time.

- Double block and bleed valves enable safe isolation, in any intervention on the process analyzer system. The sample probe is maintenance free, thereby making retraction unnecessary (unless pipeline pigging is required).

- HIFISC’s multiphobic membrane filter (HPFF) removes solids as well as polar and non-polar liquids at the inlet. By keeping reactive chemicals – glycol, amine, zinc oxide, caustic, molecular sieve dust etc. – away from the sample lines and final sample conditioning system, we can avoid absorption / desorption and reduce lag time.

- For analysis at low ppm levels, Silcosteel tubing will be necessary. As long as the tubing is protected against contaminants, the tubes inertness will remain.

- The first filter’s outlet is connected to the zero-dead-volume pressure reduction system (heated, or non-heated). The average filtration pore size is typically 500 times smaller than that of the reduction system, lowering plugging risk to near zero.

- The pressure reduction system, sample lines and conditioning system do not contain any dead volumes, and the number of fittings is minimized. This results in superior response times for measurement of moisture (H2O) and hydrogen sulfide vapor and their concentration changes.

- A second fast loop filter is used for the final conditioning step. No dead volumes are present in the flow path.

- The secondary sample conditioning system can also be installed in the analyzer house, since pressure reduction doubles as a flow limiter. Especially in tropical climates, installation of the secondary filter at the operating temperatures can help to protect against hydrocarbons and water.

The need for better sample conditioning systems

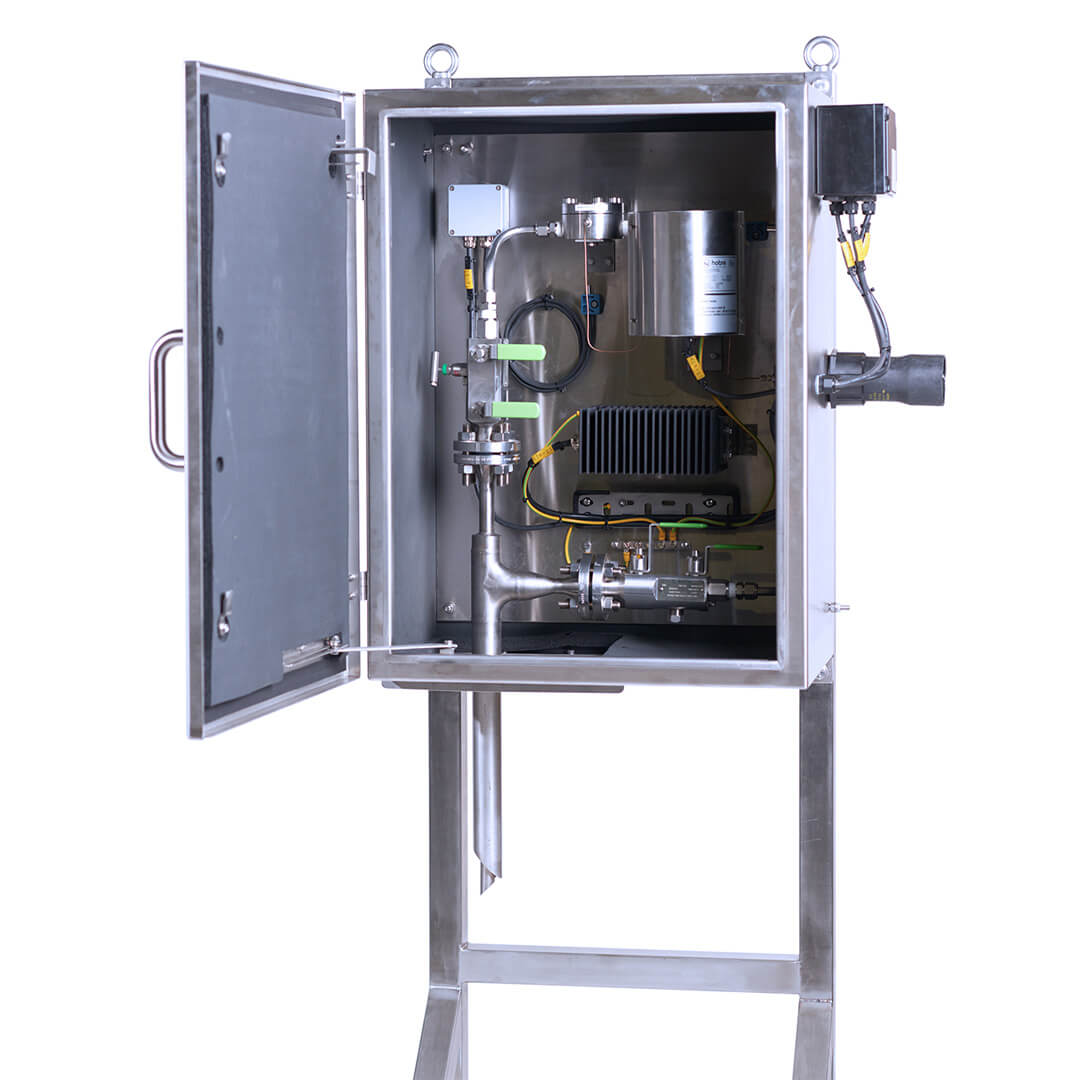

To perform a high-quality analysis it is crucial that an analyzer receives an uncontaminated gas sample. This is achieved through sample conditioning. The Hobré HIFISC can be combined with most process gas analyzers; we design and produce sample conditioning systems to meet the exact needs of each analyzer. It combines several field proven element which are selected and combined as a modular system, to solve a wide variety of applications.

Certificates