“The C-QUAND allows us to have direct and continuous insight in our process, optimizing the use of energy and chemicals”

Our Technology

The non-destructive ED-XRF, X-Ray method has a long-proven track record in the industry for the measurement of elements in liquids. The technology delivers low OPEX costs with high availability (>99.5%). The C-QUAND analyzer offers excellent repeatability with the guarantee of drift-free measurement in the low and high concentration ranges.

The C-QUAND – which has no problematic moving parts – features integrated auto-validation on a solid reference material. The heated sample cell handles more viscous samples and measures at process temperature. Both the sampling system and analyzer wetted parts are available in acid resistant materials. The net effect is a continuous, non-destructive, low maintenance analyzer with calibration intervals of typically more than one year. Considerable savings in analysis time and operational cost – in comparison to alternative analytical techniques – are two of the main benefits of the C-QUAND. It is a robust product fit for harsh process environments and can be fully integrated in process monitoring and control.

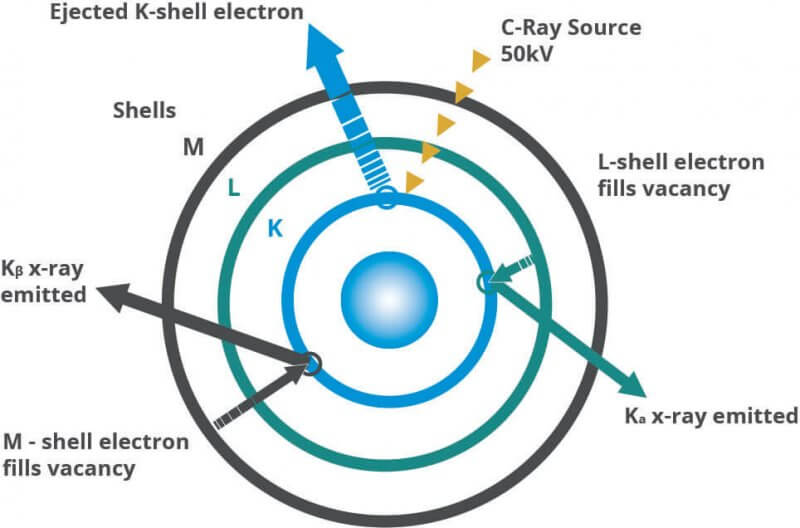

X-Ray Fluorescence Principle

The C-QUAND has a powerful 15 watt, 50 kV X-ray source, with a silver anode. The X-rays displace the inner electron out from the K or L orbit of the atom, leaving a void. The now unstable atom will immidiately fill the void with an electron from the outer orbits. The resulting reduction in energy is emitted as a photon with a specific energy level unique to that particular element. The fluorescence is captured by a silicon drift detector (SDD). It’s count rate being monitored directly proportional to the concentration of the element of interest

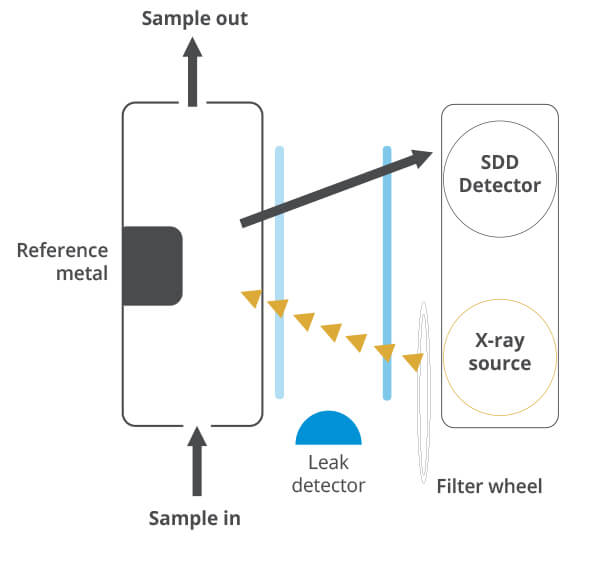

Measuring cell

The X-rays generated by the source are first filtered by one of six different optical filters. The X-rays then travel through a thin window before hitting the actual sample. The window material can be beryllium for sulfur measurement in hydrocarbons, or a polyimide such as Kapton® or Upilex® for the measurement of metals in aqueous solutions.

The measuring cell is constantly flushed with fresh samples. Importantly, this method of measurement is continuous throughout the entire measurement, not just at the beginning. The measuring cell also contains a solid reference metal, which is used for automatic gain correction.

Product Comparison

In the table below, you may find the differences of the two C-QUAND variants available:

| Model | C-QUAND-ELT | C-QUAND PLUS |

| Technology | ED-XRF | ED-XRF |

| Integrated automated flushing system | No | Yes |

| Sample Recovery System | Optionally | Optionally |

| Typical Applications | Metals refining and recycling, Waste water streams, PTA & PIA plants, and/or other acidic and aqueous samples. | (Ultra) low Sulphur measurement in fuels and/or other highly sensitive (low range) measurements that may be prone to window fouling. |

Certificates