We are the world leader and manufacturer for BTU* Analyzers on flares

*) BTU = British Thermal Unit

“The WIM COMPAS ™ after our flare recovery system is the best way to control we don’t emit any unburned hydrocarbons and monitor compliance at the lowest costs”

WIM COMPAS ™– Versions

Continuous

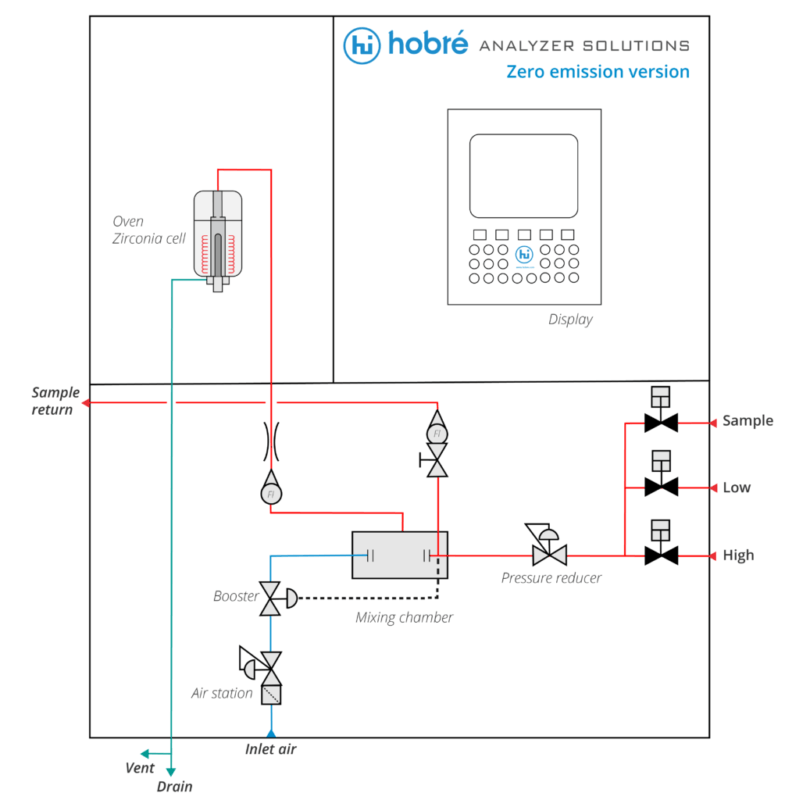

This version is designed for top performance where response time, repeatability and reliability count. A small sample flow is mixed continuously with air. The air-fuel mixture undergoes catalytic combustion followed by measurement of the residual oxygen. This provides a direct measure of CARI and correlates to the Wobbe Index as per ASTM 4891-89. By integrating a specific gravity cell, heating value and air demand are also measurable.

Infographic 1. Continuous configuration

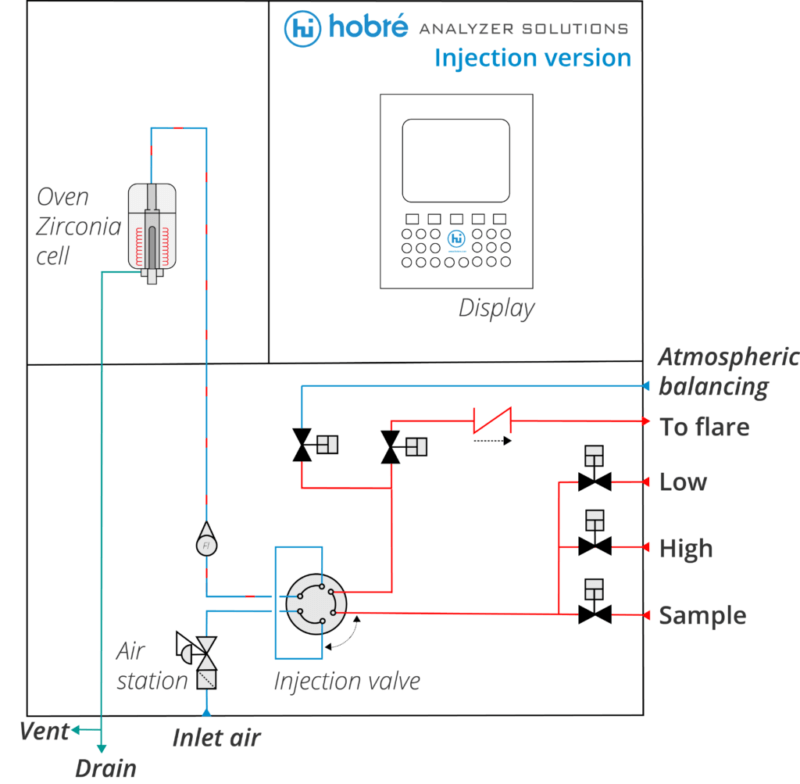

Cyclic injection

Infographic 2. Injection configuration

The WIM COMPAS™ offers an unmatched, robust solution with high availability, for Fuel and flare gas combustion measuring, such as sour gas and flare gas. Hobré has developed an analyzer especially for these kinds of applications, that injects small amounts of gas into an air stream, typically at intervals of 30 seconds. The oxygen peak size is a direct measure of the air demand and proportional to the heating value (BTU).

High-temperature

WIM COMPAS High Temp analyzer

WIM COMPAS High Temp analyzer

Keeping the gas above dewpoint is crucial to the success of most applications. The WIM Compas™ can be heated up to 55°C (131°F) as standard; high-temperature versions (up to 150°C / 300°F) are available if required

Product Comparison

In the table below, you may find the differences of the WIM variants available:

| Model | WIM COMPAS Xpress | WIM COMPAS Flex | WIM COMPAS Pulse | WIM COMPAS Pulse HT |

|---|---|---|---|---|

| Technology | Residual Oxygen method | Residual Oxygen method | Residual Oxygen method | Residual Oxygen method |

| Principle | Continuous type | Continuous type | Injection type | Injection HT |

| Typical Response | T90 <5 seconds | T90 <5 seconds | Update time 30 seconds | Update time 30 seconds |

| Gas / Application | Natural Gas, LNG – Blending, Turbine (Power) | Fuel gas – Blending, Turbine (Power), Burner/Furnace/Heater/Boiler | Blast Furnace Gas, Coke Oven Gas, Flare gas, Sour gas – Steel applications, Flaring | Flare gas, Sour gas (high dew point up to 150°C/300°F) – Flaring |

Certificates